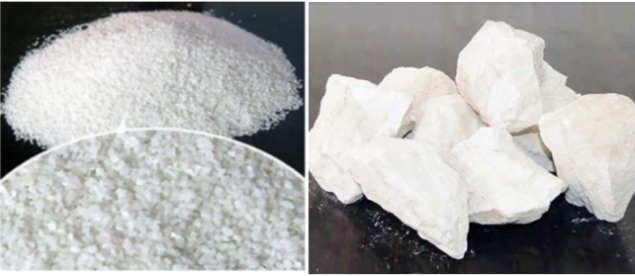

Glass Bottle Production Step 1 – Raw Material

Batching: It is a process of mixing all kinds of raw materials evenly in a mixer according to the designed material prescription. The main raw materials of glass bottle including quartz sand, limestone, feldspar, soda ash, boric acid and so on.

The difference in perfume bottle raw materials and prescription determines the quality of glass products (the difference of quality is mainly showed at color, transparency and crispness). For perfume bottle, there are several raw materials widely used: normal rough material, White material, and high white material, among them the high white material is more transparent and clear than others. We call the glass made by high white material as white opal glass which is popular in luxury niche brands for high-end market.

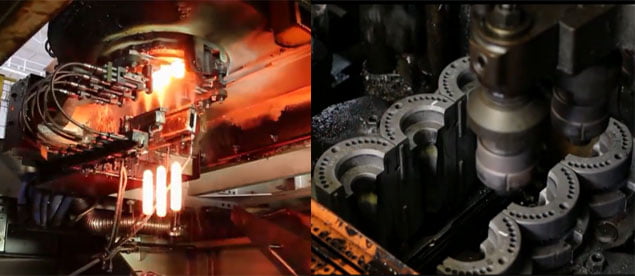

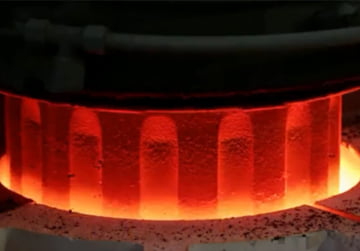

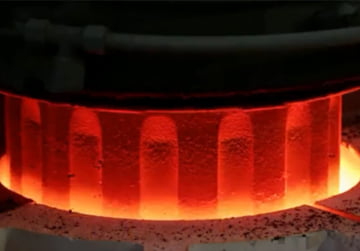

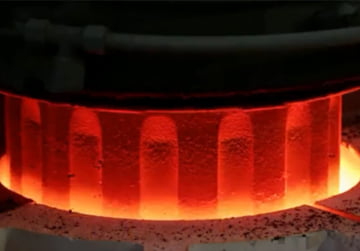

Glass Bottle Production Step 2-Melting

Melting: The raw materials of glass bottles are heated under high temperature into bubble-free glass liquid. This is a very complicated physical and chemical reaction process that is carried out in melting furnace in strict on temperature requirement.

Normally the temperature inside the melting furnace must within 1300 ~ 1600℃. The perfume glass bottles which produced at the most beginning (when the temperature not high enough) are mostly defective. During the melting process, there will produce some subtle bubbles in glass liquid if temperature inevitably changes. The common standard to judge whether a glass bottle with bubble defect or not is to see if the the diameter of bubble more than 1mm, some factory may have higher standard to serve for luxury brands high-end market. Generally, the more stable the temperature is, the better quality the glass will be.

The melting furnaces work 24h everyday; Once stopped, the life of the furnace will be greatly reduced or even damaged.

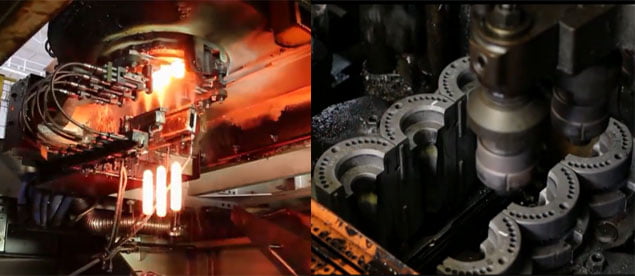

Glass Bottle Production Step 3-Forming

Forming: The transformation of molten glass into a solid product with a fixed shape. It is a process of cooling under a certain temperature, from viscous liquid state to malleable state and then to brittle solid state. Common forming methods can be divided into artificial forming and mechanical forming.

Artificial forming: Taking out a ball of semi-solidified glass from high-temperature furnace by a nickel-chromium blowing pipe,then blow it and turning around it in hand until the shape is formed. This forming way is mainly used for craft bottle in small batch.

Mechanical forming: Because of the high labor intensity, high temperature and poor condition of artificial forming, most of them have been replaced by mechanical forming in automatic I.S. glass bottle-making machine.

The main steps:

1) Cutting material: the glass liquid is cut by scissors into glass droplets of a certain weight; the electronic system controls the machine to precisely distribute the glass liquid to each trough.

2) Forming bottle neck: the glass liquid falls vertically into the initial parison mould and is blown to complete the forming of the neck of perfume bottle.

3) Forming perfume bottle complete: flip the glass bottle into a mold on the other side and blow out the body of bottle.

4) Cooling bottle: take out the glass bottle, after cooling by cooling air, transfer it to conveyor belt and enter annealing furnace.

5) Inspecting and packing